Grease Separators

The professional separation of greasy wastewater.

Grease and oil get into the wastewater of many catering and food-processing businesses (e.g. restaurants, hotels, motorway services and butchers). The wastewater has a long way to travel before it reaches the next wastewater treatment plant. A quantity of grease and food residues deposits in the drainage systems. The consequence is pipe blockage, corrosion and odour nuisance and impairment of the function of wastewater treatment and lifting stations. Therefore, the legislator requires grease separators to EN 1825 or DIN 4040 be installed in businesses in which greasy water is produced.

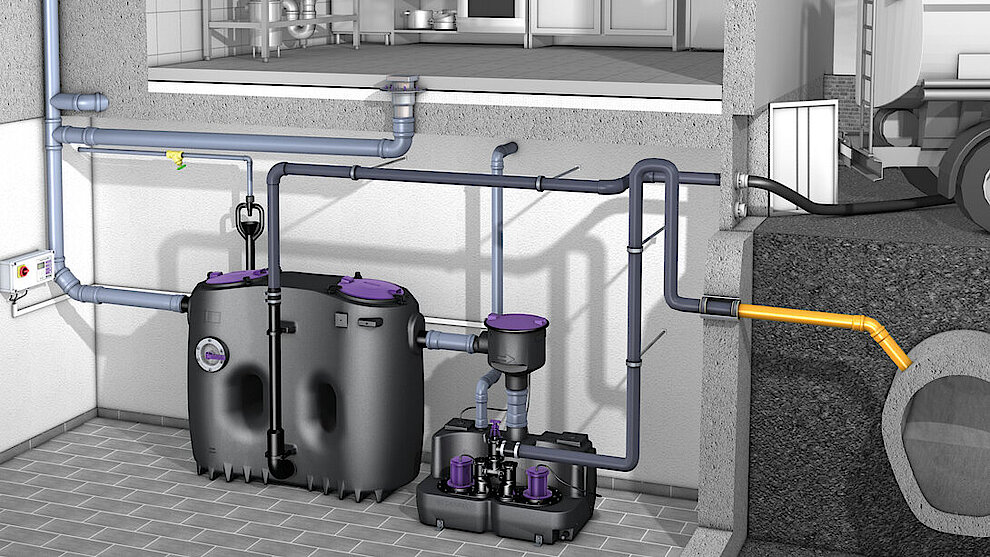

Grease separators for exposed installation

A free-standing grease separator is installed freely accessible in the building, typically in a basement room. The space available in the surrounding rooms is frequently not ideal for transporting large objects. Our EasyClean free grease separators are therefore particularly narrow. In addition, the entire technology is integrated on the base area of the tank and can therefore be set up on the wall to save space. For particularly confined entrances, we also offer the EasyClean Modular that is assembled directly in situ.

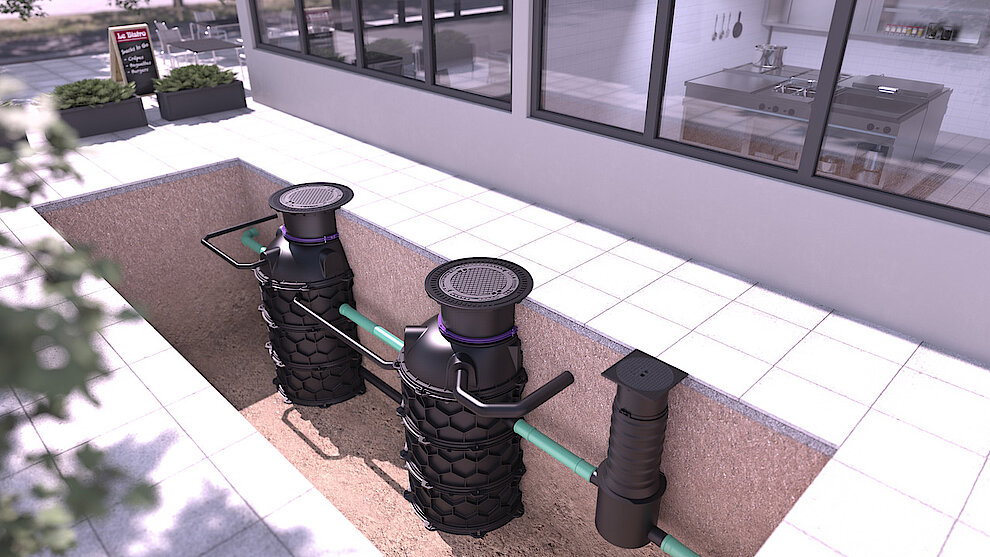

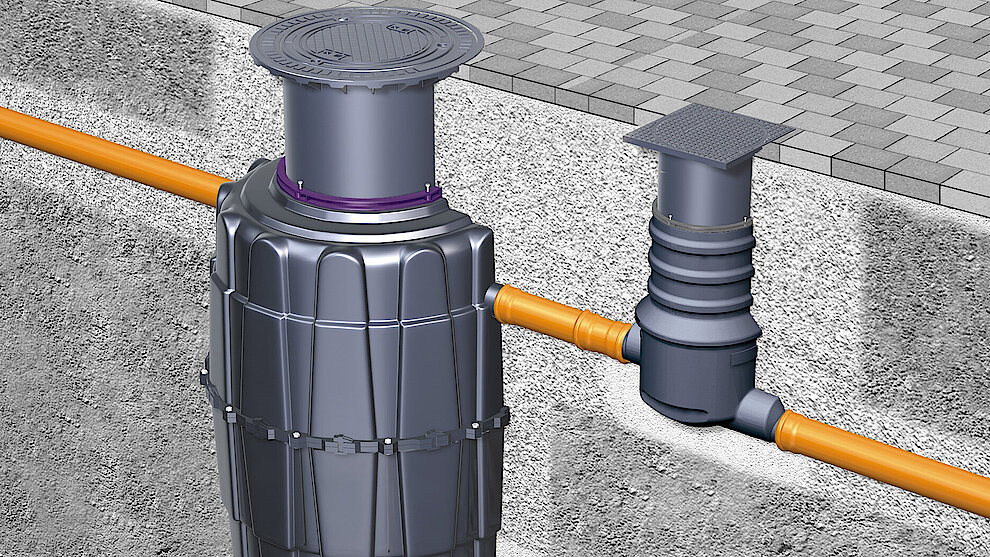

Grease separators for underground installation

Installing a grease separator in the ground offers many additional advantages: No useful space in the basement is lost, instead the entire system disappears under an odour-tight cover outside the building. The separator remains easily accessible for maitnenance and inspection via integrated steps. The complete root-proof chambers of our EasyClean ground grease separator made of polyethylene are particularly easy to place in the excavations and can be adapted individually to the ground level with the help of vertically adjustable upper sections.

More Information

According to the regulations, you must use a grease separator if you operate a catering, food processing or similar business in which greasy wastewater is produced. If you do not separate your wastewater, stubborn, foul-smelling deposits form in the drainage system, which are extremely difficult to remove. In this case, in addition to having to pay a fine you can also expect expensive damage due to pipe blockage, corrosion and malfunctioning of wastewater treatment plants and lifting stations.

Grease separators to EN 1825 or DIN 4040 are specified as a requirement to prevent these sometimes dire consequences. Grease separators must always be used if vegetable and animal grease and oil in the wastewater have to be retained. This applies to commercial and industrial businesses, e.g. to:

- Kitchen operations and large-scale catering establishments, e.g. restaurants and hotels

- Motorway service stations, canteens

- Butcher’s with and without an abattoir facility

- Slaughterhouses

- Glue factories

- Soap and stearin factories

- Oil mills

- Cooking oil refineries

- Canning factories

Statutory provision

Grease separators are required by law for fat, oil and grease contaminated wastewater streams from commercial kitchens.

Pipe blockages, corrosion and odour formation

Fat, oil, grease and food residue entering the building’s wastewater drainage pipe system results in build-up, blockage and odour issues which are difficult to handle. This results in corrosion or complete failure of the drainage pipe system.

Environmental protection

Grease separators prevent the environment from being contaminated by greasy wastewater and contribute to the trouble-free operation of sewage treatment plants.

Which nominal size of grease separator is the right one for you depends on many different factors. In addition to the wastewater produced, many other difficulty factors must also be taken into consideration. Our SmartSelect design tool for grease separators helps you to find the right product: You are first guided through individual questions, at the end of which the calculation is performed fully automatically. In this way, you find the best solution in no time.

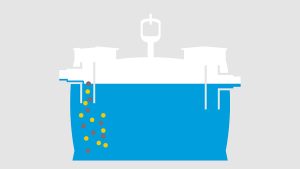

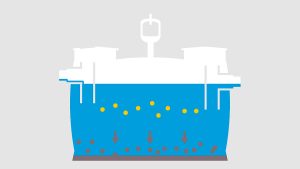

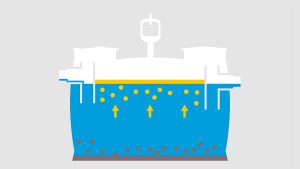

The function of grease separators is based on the principle of gravity: Due to the difference in density of water, grease and dirt particles (sludge), the different materials in the separator tank separate automatically.

Calming

The contaminated wastewater is routed into the grease separator where it is slowed down by a deflector plate.

Sludge layer

In slow-flow tanks, substances that are heavier than water sink to the bottom and settle in the sludge trap.

Grease layer

Grease and oil rise to the top and form a grease layer that is retained between the inlet and outlet.

Disposal variants - from conventional to convenient.

Grease separators must be completely emptied on a regular basis to dispose of the retained waste materials. To this end, we offer our grease separator models with different disposal variants. The options range from the normal opening of the tank to a fully-automatic disposal system.

Disposal variants

Auto Mix & Pump

Mix & Pump

Auto Mix

Mix

Direct

Standard

Disposal variants

AMP

MP

AM

M

D

S

Direct Disposal

Enables the extraction of the grease separator contents through a permanently installed disposal pipe without opening the tank.

Shredder-Mix-System

Fully mixes the contents of the grease separator into a slurry to aide in the disposal process.

Control Unit

Enables the convenient setting and control of the grease separator functions using a control unit mounted on the wall.

Disposal Pump

Handles the disposal of the grease separator in the case of longer distances between the separator and the disposal truck.

Fully Automatic

Controls the disposal and rinsing

processes fully automatically.

AMP = Auto Mix & Pump

MP = Mix & Pump

AM = Auto Mix

M = Mix

D = Direct

S = Standard